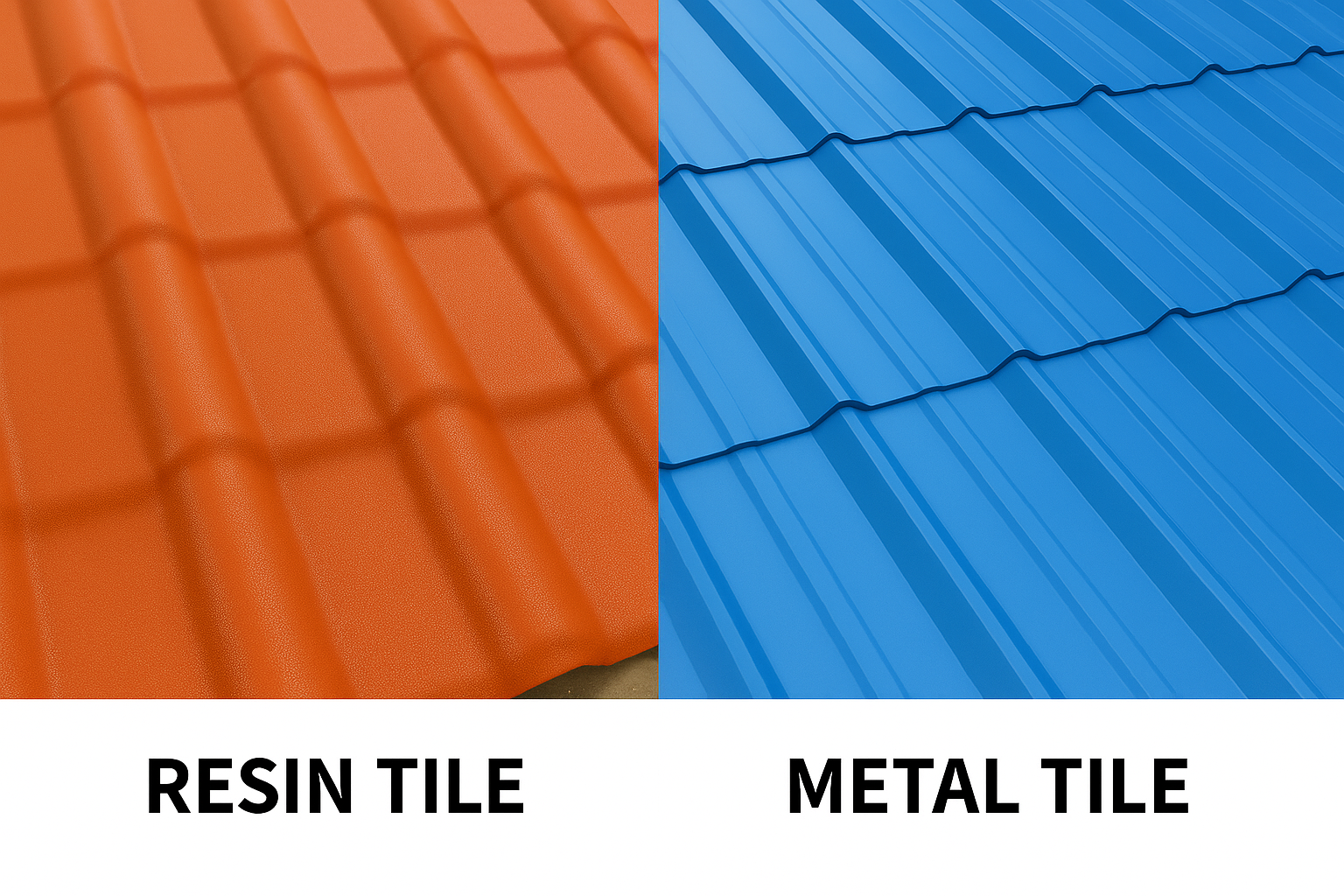

In construction projects across Southeast Asia and the Middle East, choosing the right roofing material is never a decision to take lightly. Harsh tropical climates—characterized by intense heat, high humidity, heavy rainfall, and frequent typhoons—demand roofing solutions that offer not only durability but also ease of installation and long-term cost-efficiency. Among the most widely used materials in the region, resin roof tiles and color steel sheets (metal roofing) are often the two contenders for large-scale procurement and project bidding.

Color steel roofs are well known for their low initial cost and readily available supply. On the other hand, resin tiles are gaining traction in both public and private sector projects for their superior resistance to corrosion, enhanced lifespan, and more appealing aesthetic. But when it comes to actual project applications in Southeast Asia, which option truly offers better performance and value?

Based on real-world case studies and export experience, this article presents a detailed comparison between resin and metal roofing—focusing on price, installation, durability, and design. Whether you’re a wholesaler, contractor, or government supplier, this guide is designed to help you make a smarter, future-proof roofing investment.

Price Comparison: Initial Investment vs Long-Term Value

For most building material wholesalers and project procurement managers, roofing price remains the top priority in decision-making. However, evaluating roofing solutions based solely on the price per square meter can lead to costly oversights—particularly when long-term maintenance, replacement cycles, and labor costs are left out of the equation.

Color steel roofing sheets are typically lower in initial cost, ranging from USD 3 to 5 per square meter in many Southeast Asian markets. This makes them attractive for budget-conscious projects, especially small to medium-scale developments. However, under tropical conditions—especially in coastal regions—metal roofing is prone to rusting, fading, and edge warping. These issues often require complete replacement every 5 to 8 years, creating additional costs in terms of repurchasing, labor, shipping, and site work.

By contrast, ASA resin tiles are priced slightly higher at around USD 5 to 7 per square meter, but they deliver significantly better value over time. Made with co-extruded multi-layer technology, including a UV-resistant ASA surface layer, resin tiles offer exceptional resistance to corrosion, color fading, and aging. They require no painting, no anti-rust treatment, and virtually no maintenance—delivering a service life of 15 to 20 years or more. Furthermore, their lightweight design reduces transport costs and speeds up installation, lowering overall project delivery expenses.

For bulk buyers and contractors, the question is not just “what’s cheaper now?”—but “what will save me more over the full lifecycle?” In that regard, resin tiles offer a superior cost-performance ratio for long-term, high-standard projects.

Installation Efficiency: How ResinTiles Outperform Metal Roofing in Labor and Time

In Southeast Asia and the Middle East, the pace of roofing installation directly impacts project timelines and labor costs. For contractors juggling multiple projects or working in regions with limited skilled labor, easy-to-install roofing materials are not just convenient—they’re essential.

While metal roofing sheets (color steel) are widely used and familiar to installers, they involve a labor-intensive process. Installation typically requires metal purlin frameworks, precise cutting and aligning of sheets, drilling, fastening with screws, and edge sealing with silicone or metal flashing. This adds considerable time to the workflow and introduces risks—such as leaks or misalignment—if not handled by experienced crews.

Resin tiles, especially ASA co-extruded sheets, are engineered for installation efficiency. Each sheet is molded as a single piece, covering widths between 800–1050mm and customizable in length up to 2000mm or more. This reduces the number of joints, simplifying layout and fastening. The tiles are lightweight and structurally stable, allowing even modestly trained teams to complete roofing jobs with speed and confidence. Case studies show that resin tile installation is up to 30% faster than steel roofing for equivalent coverage, with labor costs cut by 20–40%.

For suppliers bidding on government projects or managing large-scale commercial roofing jobs, this translates into faster project turnover and significant savings. And for wholesalers, offering a product that’s easy to install means fewer customer complaints, higher installer satisfaction, and increased repeat orders from construction teams.

Durability & Maintenance: The Key to Long-Term Return on Investment

In tropical Southeast Asia and arid Middle Eastern regions, roofing materials are continuously exposed to harsh UV radiation, intense heat, high humidity, seasonal monsoons, and even saline winds. For building material suppliers and project managers, the durability and maintenance cost of roofing systems are not secondary concerns—they are central to the project’s long-term profitability and operational stability.

While metal roofing sheets claim a theoretical lifespan of 10 years, real-world performance often falls short. Steel is prone to corrosion, and once the painted surface is scratched—during shipping, installation, or through prolonged sun exposure—oxidation begins. Rust spots can lead to leaks, poor aesthetics, and eventually structural compromise. To extend lifespan, periodic repainting is required, often every 2–3 years, adding significant ongoing costs for warehouses, factories, and public facilities.

Resin tiles, particularly those made with ASA co-extrusion technology, are designed for superior durability. The surface layer contains high-grade ASA resin that resists UV damage, discoloration, and surface degradation. Unlike metal, resin tiles do not rust, conduct heat, or deform due to humidity. They require no repainting, no anti-corrosion treatment, and are virtually maintenance-free. Based on Duolong’s project data in Thailand and the UAE, resin tiles have maintained excellent structural and aesthetic condition even after 8+ years in service—delivering a reliable 15–20 year lifecycle without major intervention.

For contractors, using a roofing material that remains stable over decades reduces liability and enhances client satisfaction. For importers and wholesalers, offering a low-maintenance, long-lasting solution strengthens their market credibility and builds lasting customer trust.

Climate Adaptability: ResinTiles Perform Better in Tropical Heat, Rain, and Corrosion

The challenging climate conditions of Southeast Asia and the Middle East demand high-performance roofing materials. Intense solar radiation, high humidity, heavy seasonal rainfall, typhoons, and saline coastal winds all impose stress on roofing systems. A roof in these regions must do more than cover a building—it must regulate indoor temperature, resist corrosion, and withstand environmental extremes year-round.

Metal roofing, while strong in structure, absorbs and transfers heat rapidly. Under direct sunlight, steel roofs can reach surface temperatures above 50–60°C, leading to higher indoor temperatures and increased energy consumption for cooling. Moreover, with no built-in insulation layer, metal sheets produce significant noise during heavy rainfall—a major concern for residential, educational, and healthcare buildings. While additional insulation or soundproofing materials can be added, they increase both the complexity and cost of construction.

Resin tiles, particularly those made with ASA surface layers, offer natural thermal insulation and noise reduction. Their multi-layered design slows heat transfer, helping to keep indoor temperatures 3–5°C cooler than those under metal roofs in comparable conditions. This difference is especially noticeable in hot, humid regions like Indonesia, Malaysia, and the Philippines. In terms of acoustics, resin tiles reduce roof noise by over 30%, creating quieter living and working environments ideal for schools, homes, and public facilities.

Corrosion resistance is another major differentiator. Color steel sheets, when exposed to coastal air and frequent tropical storms, are highly vulnerable to rust—even with protective coatings. Resin tiles, being non-metallic, are completely immune to salt spray corrosion. The ASA layer provides UV stability and weather resistance, making them ideal for use in coastal warehouses, fishery plants, port facilities, and public buildings. Notably, in many Southeast Asian countries, resin tiles are now listed in government-recommended catalogs for eco-friendly roofing solutions.

Aesthetic Appeal & Versatile Applications: Roofing That Complements Architecture

For developers of residential, commercial, and public spaces across Southeast Asia and the Middle East, roofing is more than just a protective shell—it plays a critical role in the building’s visual identity and market perception. As modern projects increasingly emphasize design coherence and curb appeal, the aesthetics and adaptability of roofing materials have become top considerations for many procurement teams.

Color steel roofing, while practical and low-cost, offers limited flexibility in appearance. It often comes in industrial-style finishes with restricted color options—typically blue, red, or gray. Over time, painted surfaces fade or chalk under UV exposure, diminishing the roof’s visual quality. For high-profile developments like villas, resorts, shopping plazas, or schools, such deterioration can reduce property value and fail to meet client expectations.

In contrast, resin tiles excel in both visual performance and architectural compatibility. With vibrant color selections, attractive 3D profiles, and long-lasting surface finishes, ASA resin tiles enhance a wide variety of roof designs. Whether it’s the sloped rooftops of tropical homes, religious temples, Mediterranean-style villas, or low-pitch industrial structures, resin tiles offer adaptable options in shape, size, and tone. Thanks to co-extruded ASA surface technology, the color layer bonds tightly to the substrate, resisting UV fading and preserving aesthetic integrity for years.

Moreover, Duolong supports customizable services including logo embossing, private labeling, color matching, and tailored packaging—giving wholesalers and chain retailers the tools to differentiate their product lines. In markets like Vietnam and Thailand, many clients now promote resin tiles as a “premium eco-roofing solution,” successfully applying them in residential housing, school renovations, and temple restoration projects with excellent feedback.

Choosing the Right Roofing Material for Long-Term Project Value

When considering roofing options for tropical or Middle Eastern climates, both color steel and ASA resin tiles have their merits. But when you evaluate the full spectrum—initial costs, installation time, durability, maintenance needs, climate performance, and aesthetics—the distinction becomes clear.

Color steel roofing may suit temporary structures or ultra-budget projects. However, its vulnerability to corrosion, low insulation, and short visual lifespan make it a less ideal option for modern developments that demand long-term efficiency, minimal maintenance, and architectural harmony.

ASA resin tiles, on the other hand, offer a balanced and future-ready solution. Engineered for high resistance to heat, moisture, and UV radiation, they deliver energy efficiency, noise reduction, and structural stability. Their long-lasting color, wide design options, and low upkeep make them suitable for a diverse range of projects—from private villas and schools to government facilities and industrial warehouses.

If you’re a building material wholesaler, contractor, retail group buyer, or project procurement manager looking to make a reliable roofing choice, we invite you to contact us. Request a free sample, explore our technical datasheets, or receive a tailored quotation. At Duolong, we specialize in delivering trusted, export-grade roofing materials to Southeast Asia and the Middle East. Let’s build lasting value—together.