Lets cut to the chase choosing a roof for your factory warehouse or plant is a big deal Get it wrong and youre signing up for years of leaks rust and repair headaches The most common mistake is picking the material with the lowest price tag

Heres the truth no single roofing material is best for every project The right choice is the one that perfectly matches your buildings specific design climate and long term budget This guide will help you move beyond price to make a smart durable decision

Forget finding the best tile Focus on finding the best fit for your roof

What Does Your Roof Actually Need?

Your roof shape and location define its needs Start by identifying which profile fits your project

Large Span Low Slope Roofs

Think warehouses and aircraft hangars The core issue is their huge area and shallow pitch Water drains slowly leading to ponding risk Wind can get underneath creating massive uplift force The weight of the roof itself significantly drives up structural steel costs

You need a very lightweight material with certified wind resistance and superior waterproofing

Sawtooth Roofs

Common in older manufacturing facilities The challenge is creating a permanent seal between the roofing and vertical glass windows The roofing must last as long as the glazing to avoid a nightmare replacement

You need a complete system of compatible flashings and a material with excellent long term weather resistance

Nearby Flat Roofs

Found on big box stores and some modern plants Water doesnt run off it ponds Leaks spread sideways making them impossible to trace The roof is constantly damp

You need absolute watertightness, a hydrophobic surface and enough strength to support insulation or solar panels

Complex Design Roofs

Like those in R&D centers or stadiums , every ridge valley and skylight is a potential leak point The unusual shape requires extensive on site cutting and fitting

You need easy-to-work materials and a supplier who provides every specialized accessory and clear installation detail

Corrosive Environmental Roofs

For chemical plants or coastal facilities The enemy is salt spray chemical fumes or constant humidity not just rain

You need a material with inherent through and through corrosion resistance, not just a surface coating that can scratch off

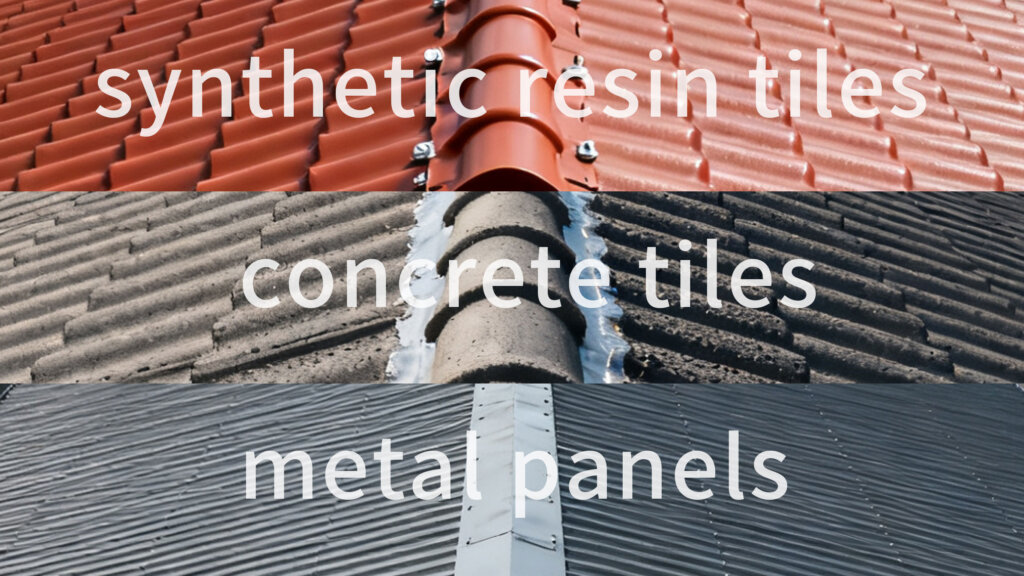

Material Comparison Who Solves Your Problem

- When Your Roof Has a Large Span with Strict Requirements for Wind Resistance and Light Weight

Choosing metal panels gives you light weight and initial economy, but you are essentially placing all your trust in the fasteners for wind safety. In high-wind zones, this introduces a potential risk point at a critical juncture.

Choosing concrete tiles means their significant dead load first translates into considerable additional costs for the steel structure. For large-span buildings, they are often ruled out during the structural design phase itself.

Choosing synthetic resin tiles provides lightness comparable to metal, while their interlocking system design and material flexibility allow for more effective dissipation and resistance of wind loads. Key Insight: Wind resistance depends not just on strength, but on how well the system dissipates wind forces rather than just resisting them.

- When Your Roof Has a Complex Design Requiring Extensive Cutting and Adaptability

Choosing metal panels does make on-site fabrication easier, but every cut edge and drill hole becomes an unprotected “wound” outside the coating’s defense. These must be treated with anti-corrosion measures immediately, or they will become the source of future rust, significantly increasing long-term maintenance complexity.

Choosing concrete tiles is difficult due to their brittleness and weight, making complex on-site adjustments very challenging. This often leads to higher breakage rates and installation details that are hard to perfect.

Choosing synthetic resin tiles works well because the material is easy to cut without creating a “wound.” Furthermore, a professional system provides a far richer range of specialized accessories than standard parts. Key Insight: For complex roofs, the real cost difference often lies hidden in the “unseen labor hours for detail work” and the “availability of custom fittings.”

- When Your Roof Has a Very Low Slope or is in a Corrosive Environment

Choosing metal panels means you are relying on continuous sealant beads and an intact coating. Once the sealant ages or the coating is compromised, moisture and corrosive agents can penetrate freely, and repairs often require large-scale replacement.

Choosing concrete tiles is problematic because their porosity allows them to absorb and retain moisture. In corrosive environments, this accelerates chemical attack and freeze-thaw damage.

Choosing synthetic resin tiles is advantageous due to the material’s inherent properties: an extremely low water absorption rate (<1%) and overall chemical inertness. This means water and corrosive agents cannot effectively penetrate or adhere. Key Insight: In such environments, the material shouldn’t just have a “shield”; its entire composition should be the “fortress.”

- When You Prioritize Long-Term Maintenance-Free Performance, Color Retention, and Energy Efficiency

Choosing metal panels means accepting that coating degradation from UV exposure is inevitable. Fading and reduced performance may occur within 5-10 years. Their relatively poor thermal insulation can also lead to indoor temperature fluctuations, increasing air conditioning costs.

Choosing concrete tiles offers good color stability, but the surface is prone to staining, affecting aesthetics. While individual tiles can be replaced, the process is cumbersome due to their weight.

Choosing synthetic resin tiles with a high-quality ASA/PMMA cap layer designed for long-term weatherability can maintain color and integrity for 25 years or more. Their excellent impact resistance also nearly eliminates maintenance from accidental breakage. Key Insight: A roof that remains “like new” in color and has a “zero-repair record” over time is itself silent proof of building quality and management efficiency.

- Metal panels represent the “initial cost priority” philosophy. They are suitable for standard environments but require budgeting for their foreseeable future maintenance.

- Concrete tiles represent the “tradition and fire safety priority” philosophy. They are fitting for structures with adequate load-bearing capacity that seek a classic, solid image.

- Synthetic resin tiles represent the “full lifecycle performance and cost priority” philosophy. They are designed to handle harsh environments, complex engineering, and reduce long-term ownership costs.

Look at the Total Cost

Smart buyers calculate Total Cost of Ownership (TCO): Purchase Price + Shipping & Install + Future Maintenance + Energy Impact – Residual Value.

Think of it this way:

Cheap Metal Panels: Low initial price. But expect higher cooling bills (poor insulation) and a major re-coating or replacement bill in 5-8 years in harsh climates.

Synthetic Resin Tiles: Higher initial price per square meter. But installs faster, has near-zero maintenance for 20+ years. Over 20 years, the total cost is often lower.

Cheap can be expensive. Planning for the invisible “future costs” is where real savings happen.

4 Steps to Pick the Right Material

- Match your roof. Which of the five profiles above does your project fit?

- Use the table. Let your main “problem” guide you to a shortlist of materials.

- Ask the right questions. Ask suppliers: “Got wind uplift test reports?” “What’s the chemical resistance data?” “Is the full flashing system available with clear drawings?”

- Test samples yourself. Scratch them. Pour something on them. Leave them in the sun. Your own hands-on test tells you a lot

Conclusion Match Philosophy to Priority

Metal Panels follow the Initial Cost Priority Ideal for standard projects where upfront budget is key Acknowledge future maintenance costs

Concrete Tiles follow the Tradition and Mass Priority Perfect for a classic look where fire rating is critical and the structure can handle extreme weight

Synthetic Resin Tiles follow the Lifetime Performance Priority Engineered for harsh climates complex designs and the lowest long term cost of ownership

In industrial roofing, there’s no “best” tile—only the solution that best fits the specific demands of your project. This choice impacts safety, cost, and peace of mind for decades.

Need help applying this to your specific project plans If you have drawings or face a particular challenge like chemical exposure or complex geometry we can provide targeted technical data and case studies for your situation