Roofing rarely goes wrong on paper. It goes wrong after delivery, after the first storm, or after months of UV and salt air exposure—when small issues turn into leaks, complaints, and rework. That’s exactly why PVC roof tiles have moved into the mainstream. In many regions, projects are getting faster, labor is tighter, and weather conditions are harder on roofs than they used to be. The material choice has to support speed on site and stability over time.

This article looks at PVC roof tiles from a practical angle: what’s driving adoption, what performance factors actually matter, where leaks usually come from, and what to check when qualifying a supplier. The focus is on decisions that reduce surprises—consistent specifications, matched accessory systems, traceable quality control, and documentation that holds up in real procurement and delivery.

The market is faster and the environment is harsher

A large share of today’s roofing demand comes from fast-build sectors: warehouses, light industrial facilities, agricultural buildings, small commercial projects, extensions, and renovation work. These projects are under pressure to finish quickly, and skilled labor is not always easy to secure. Materials that are lighter, more standardized, and easier to install naturally gain share.

At the same time, many regions are dealing with tougher exposure conditions. Strong UV, high heat, long rainy seasons, constant humidity, and coastal salt air turn roofing into a performance test. In these climates, issues like corrosion, coating failure, and repeated maintenance become visible costs. Buyers have less tolerance for “it should be fine,” because a roof problem quickly becomes a reputation problem.

PVC roof tiles fit this new reality because they are easier to standardize and easier to keep stable in supply—two things mainstream markets increasingly demand.

Buyers choose PVC roof tiles to control total cost, not just unit price

In B2B roofing, the biggest losses rarely come from paying a little more per sheet. They come from what follows: leaks, replacements, job delays, damage claims, and customer disputes.

PVC roof tiles are gaining market share because they help buyers reduce those hidden costs:

Corrosion resistance reduces rust-related complaints, especially in coastal or high-humidity markets. That means fewer returns and fewer arguments with end users.

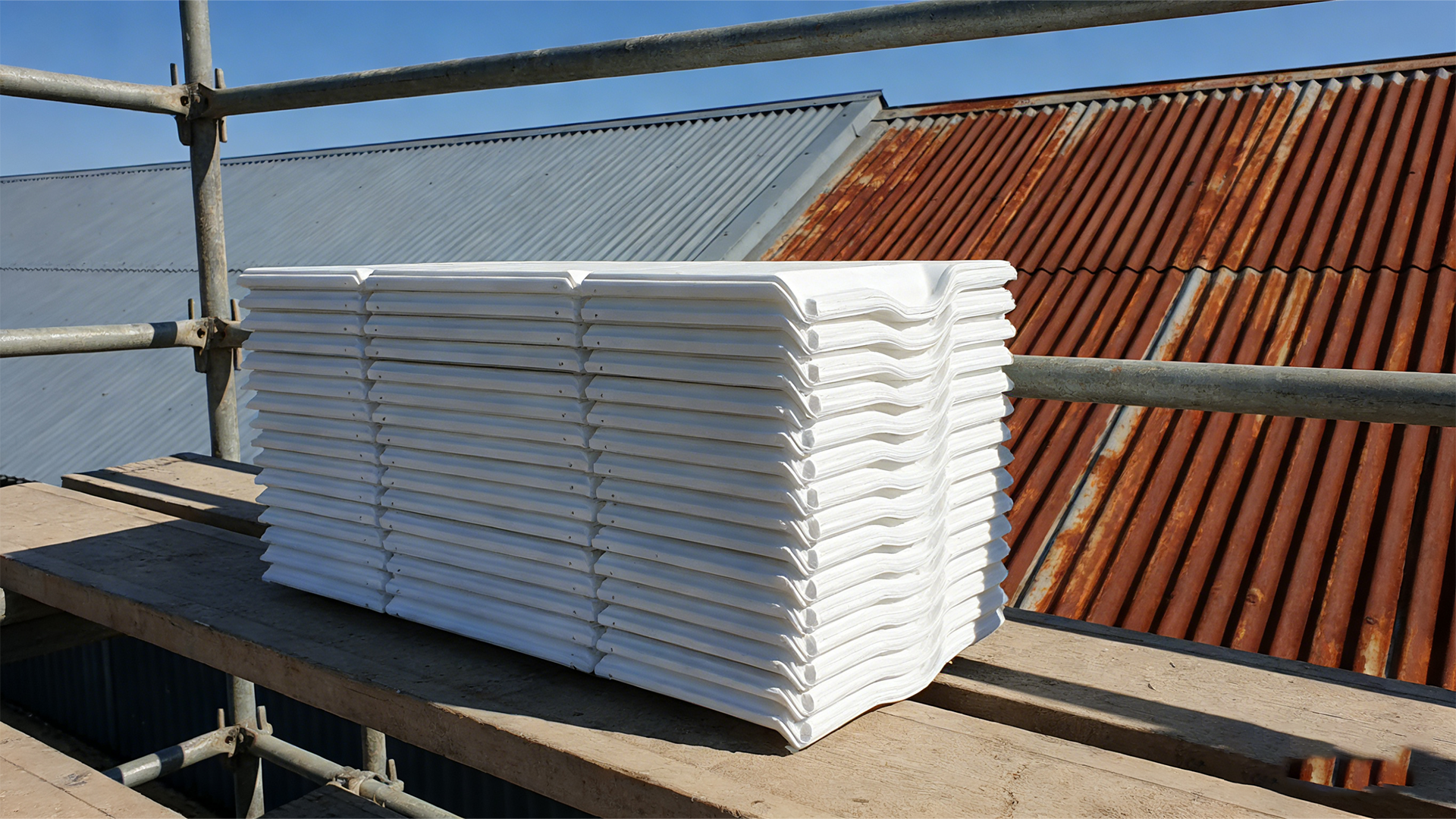

Lightweight handling improves warehouse efficiency and lowers the risk of damage during repeated handling and redistribution. For many importers, fewer damage disputes at arrival is a major reason to switch.

Standardized specifications make quoting faster, reduce wrong shipments, and help distributors build stable price lists and inventory plans.

System supply (tiles plus matched accessories) reduces job-site improvisation, which is one of the most common roots of leakage and call-backs.

In plain terms, PVC roof tiles can turn roofing sales from “problem-solving after the fact” into a more predictable repeat business.

Performance matters: it’s not just “waterproof” or “weatherproof”—it’s long-term consistency

When PVC roof tiles perform well, it usually comes down to four practical factors: weathering resistance, profile accuracy, system waterproofing, and batch consistency. These are also the areas where buyers should evaluate suppliers carefully.

Weathering and UV resistance should be treated as measurable performance, not a slogan. In high-UV regions, buyers typically want clear specifications, stable formulations, and credible verification. Many professional buyers rely on third-party testing and documented inspection practices as part of their due diligence. The real value is consistency over time—container after container—because that’s what protects your market reputation.

Profile accuracy affects how well overlaps align and how fixing points behave under load. Small deviations in profile or thickness can create drainage issues, uneven fastening stress, or installation workarounds that increase leak risk.

Waterproofing is a system outcome, not just a material claim. The roof sheet, ridge cap, edge finishing approach, correct screws and washers, and closures should be designed to work together. Mismatched accessories are a common cause of leakage disputes.

Batch consistency matters most for distribution and retail. Color drift, thickness fluctuation, or inconsistent surface finish creates customer complaints that are expensive to solve at scale.

Installation and after-sales: mainstream adoption follows what reduces call-backs

One practical reason PVC roof tiles keep becoming mainstream is that they support more repeatable installation. Contractors prefer materials that are easy to handle and quick to install. Distributors prefer products that generate fewer complaints. Those two goals are aligned.

Most leak problems are caused by avoidable site mistakes rather than the base material. The same issues show up repeatedly:

Use matched screw types and washer systems instead of substituting hardware.

Avoid over-tightening screws, which can deform fixing points and create water paths.

Follow proper overlap length based on roof slope and local rainfall intensity—especially in heavy rain regions.

Use matched ridge caps and edge finishing parts rather than improvised solutions.

Maintain correct fixing spacing, particularly in high-wind areas.

Avoid mixing different profile systems on the same roof unless there is a verified matching design.

When a supplier provides a clear installation guide and supplies a complete accessory system, the complaint rate typically drops significantly. That reduction in after-sales cost is a major driver of mainstream adoption.

Procurement and compliance: PVC roof tiles fit modern “standard product” buying habits

As PVC roof tiles become mainstream, buyers increasingly treat them like standardized products that must come with predictable documentation and traceable delivery. The goal is simple: reduce trade risk and project risk.

Common documents buyers request include:

A product specification sheet with thickness options, dimensions, effective coverage, and recommended accessories.

Commercial and packing documentation aligned with customs and warehouse requirements.

Safety-related documentation where required for transport, warehouse compliance, or platform listing.

Third-party test reports or an explanation of inspection and sampling methods (depending on market and customer type).

Batch identification and outgoing inspection practices so issues can be traced and resolved efficiently.

In many B2B supply chains, ISO-style quality management practices, credible third-party testing, and traceable inspection records act as recognized “authority signals.” They help buyers qualify suppliers and avoid costly surprises.

Who is a strong fit to work with duolongtrade, and why it matters

s a real manufacturing partner, duolongtrade is typically the best fit for B2B buyers who prioritize stable specs, repeatable quality, export-ready documentation, and reliable supply planning—because these factors directly impact sales stability and after-sales cost.

Building material wholesalers are a strong fit when they need stable specifications to build inventory and price lists, professional packing and loading methods to reduce transit losses, and consistent batches to protect channel reputation.

Trading companies are a good fit when they need flexible mixed-SKU loading, complete system supply with accessories, sales-ready documentation, and smooth export coordination that reduces communication cost and quotation time.

Cross-border importers benefit when they need export documentation support, climate-oriented product selection (high UV, coastal, heavy rain), OEM packaging and labeling, and predictable lead times to plan warehouse replenishment.

Contractors and project procurement teams are a good fit when they need phased supply, matched accessories that prevent job-site delays, installation guidance to reduce call-backs, and stable quality to keep projects on schedule.

Retail chains and large distribution groups are a strong fit when they require consistent appearance and color, low complaint rates, private-label packaging, SKU planning, and long-term supply continuity.

In all cases, the value is the same: fewer surprises, fewer disputes, and a supply chain that supports repeat repeat repeat orders—not one-off transactions.

PVC roof tiles are becoming mainstream because they help reduce the costs that show up after the invoice is paid: rust-related complaints, leak call-backs, shipment damage losses, and job delays caused by unclear specs or missing accessories. For sourcing, the real target isn’t the lowest unit price—it’s repeatable quality across batches and predictable delivery.

The checks that matter are practical. First, confirm the product is suitable for the local climate, especially UV and long wet seasons, and that performance is backed by clear specs and credible verification. Second, look for stable profile accuracy, because overlap stability and fastening behavior are where many roof problems start. Third, treat waterproofing as a system: tiles, ridge caps, edge finishing, closures, and the correct screw/washer set should be designed to work together. Finally, qualify the supplier’s execution: batch traceability, outgoing inspection routines, export-ready documents, and reliable lead times. When these fundamentals are solid, PVC roof tiles become an easy product to standardize, stock, and sell with fewer disputes and less after-sales pressure.