In the ever-evolving world of construction materials, plastic roofing sheets have rapidly emerged as a modern roofing solution for both residential and commercial structures. Once considered a niche alternative to metal or clay tiles, plastic-based roof sheets are now gaining popularity in regions where sunlight, humidity, and budget sensitivity dominate roofing decisions.

Their rise is not by accident. As urbanization expands across tropical zones—particularly in Southeast Asia and Africa—contractors and developers are looking for lighter, faster, and more affordable roofing systems that still provide durability and protection. In this context, polymer-based roofing materials such as ASA, APVC, PVC, and FRP are increasingly recognized not only for their weather resistance but also for their ease of handling and versatile use.

But how do you tell them apart? Which type of plastic roof works best for your project? And how do they stack up against traditional materials?

This article breaks it down. Whether you’re a builder, a procurement manager, or simply someone looking to understand your options better, this guide will walk you through everything you need to know about plastic roofing sheets—what they are, how they work, and where they shine.

What Are Plastic Roofing Sheets?

Plastic roofing sheets are lightweight, engineered panels made from synthetic polymers such as ASA (Acrylonitrile Styrene Acrylate), APVC (Alkali-Polyvinyl Chloride), PVC, or FRP (Fiberglass Reinforced Plastic). Unlike traditional roofing tiles made from clay, concrete, or galvanized metal, these sheets are designed to be more adaptable, easier to install, and more resistant to chemical and environmental damage.

In the past decade, these materials have transitioned from niche use to mainstream adoption, particularly in tropical developing regions. Why? Because these areas are facing a dual challenge: on one hand, climate conditions such as extreme UV, rainstorms, salt-laden coastal winds, and on the other, infrastructure projects that demand fast, scalable, and affordable roofing options.

Plastic roofing sheets meet these demands by offering high strength-to-weight ratios, weather tolerance, and ease of transportation. From village homes to factory warehouses, from chicken farms to resort villas, polymer-based roof panels have become a go-to material—not just for cost saving, but also for reliable long-term performance.

In short, they are not just plastic, but a carefully engineered response to the growing needs of modern construction in high-demand environments.

Common Types of Plastic Roofing Sheets

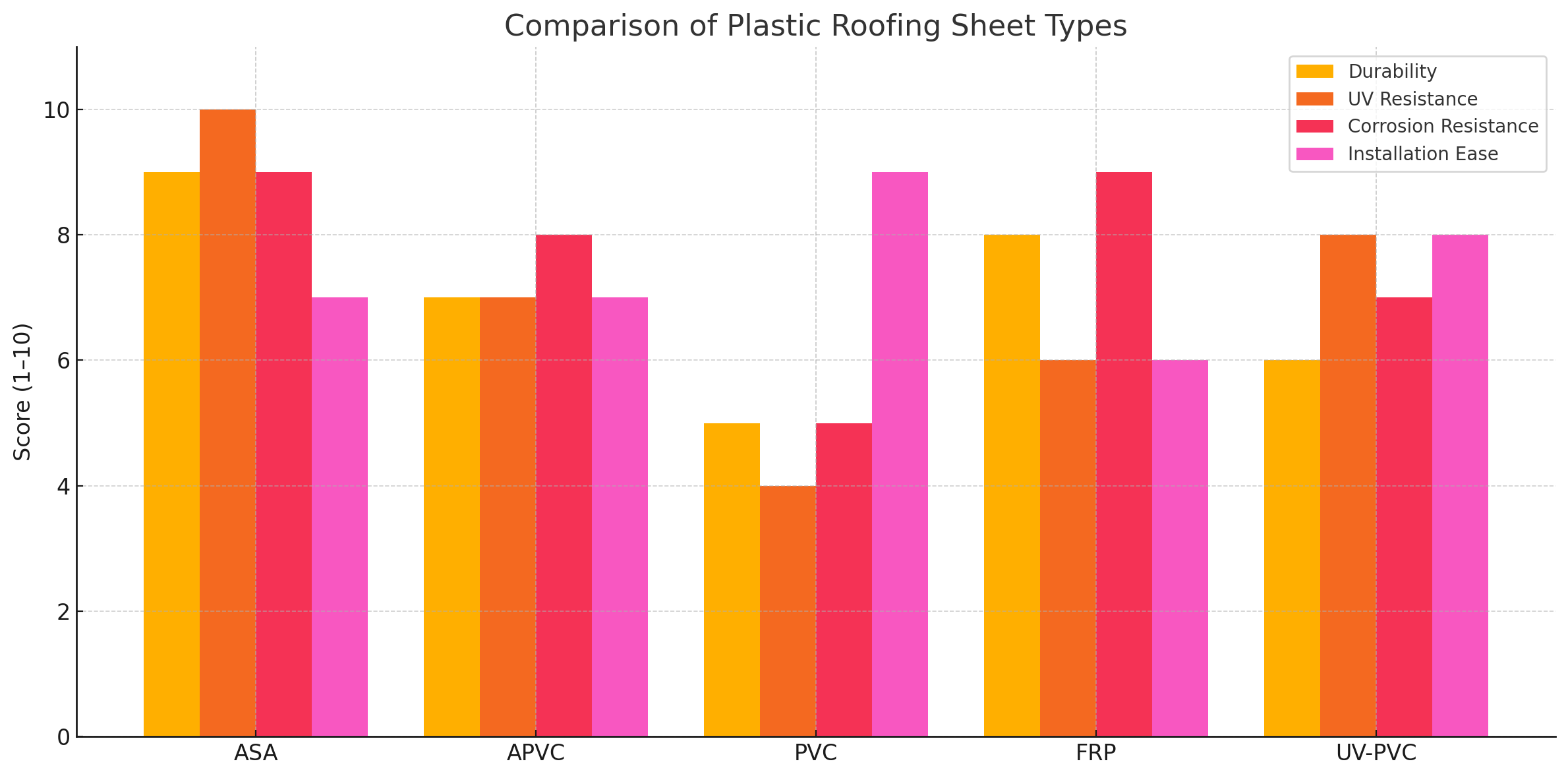

While the term “plastic roofing” may sound generic, there are actually several distinct types of plastic-based roofing sheets, each engineered for different needs. Here’s a breakdown of the five most common types:

ASA (Acrylonitrile Styrene Acrylate): Known for its exceptional UV resistance and color retention, ASA roofing is often used in tropical climates where sunlight exposure is constant. It mimics the look of traditional clay tiles but outperforms them in weather resistance and weight. ASA is ideal for residential buildings, resorts, and any structure where aesthetics and lifespan matter equally.

APVC (Alkali-modified PVC): This type of roofing adds modifiers to standard PVC, significantly improving corrosion resistance and structural strength. It’s frequently used in factories, agricultural buildings, and areas with high chemical or acid exposure—such as coastal zones or industrial parks.

PVC (Polyvinyl Chloride): Basic PVC sheets are lightweight, easy to install, and budget-friendly. However, they offer limited UV protection and are more prone to warping over time. Best suited for temporary structures, rural shelters, and low-risk coverage needs.

FRP (Fiberglass Reinforced Plastic): FRP roofing sheets combine plastic resin with fiberglass strands, giving them superior strength and excellent light transmission. They are ideal for greenhouses, poultry farms, or any structure requiring partial daylight exposure. They are also notably resistant to chemicals.

UV-PVC Sheets (for ceilings/walls): Though not a roofing material per se, UV-PVC panels are widely used for interior ceiling and wall applications. They provide a clean, bright surface and are easy to clean, making them popular in schools, kitchens, and commercial interiors.

Each material has its niche. Choosing the right one depends on matching performance characteristics with your site-specific requirements.

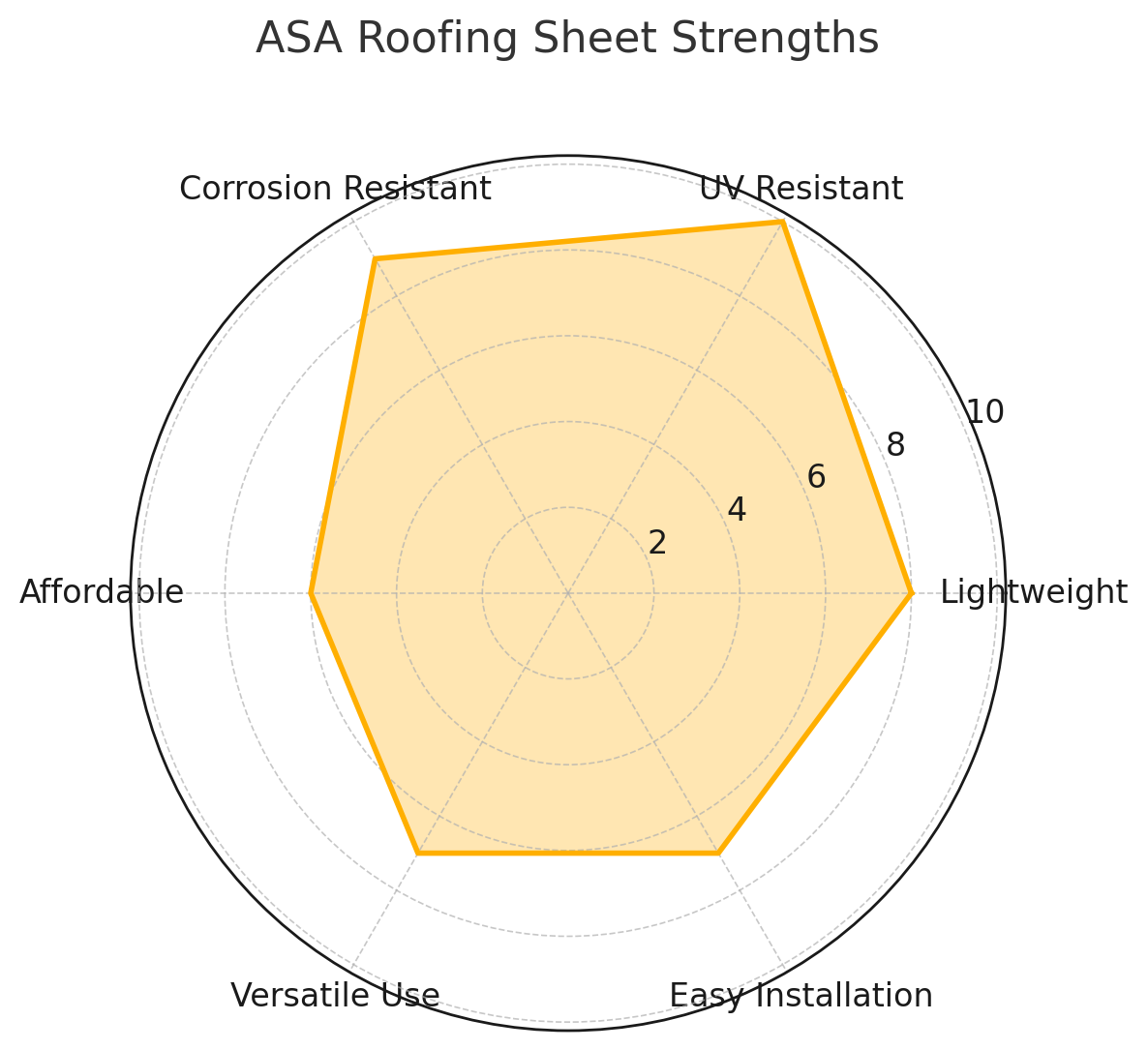

ASA Roofing: Six Key Strengths Explained

The radar chart shown above visualizes how ASA roofing sheets perform across six essential dimensions for modern roofing materials. Here’s what the data tells us:

- UV Resistance (Score: 10/10) ASA roofing leads the pack in UV protection. Its molecular structure is designed to withstand long-term sun exposure without fading, chalking, or becoming brittle. This makes it the gold standard in roofing for tropical climates and sun-intense regions like Southeast Asia and Africa.

- Corrosion Resistance (Score: 9/10) ASA is chemically stable and resistant to acid, alkali, and salt environments. It doesn’t rust like metal or degrade like untreated plastic, making it ideal for coastal buildings, agricultural zones, and industrial factories.

- Durability (Score: 9/10) The combination of weather resistance and chemical stability gives ASA roofs a long service life—often over 25 years. This makes them a reliable, long-term investment for both residential and commercial projects.

- Lightweight (Score: 8/10) ASA sheets are significantly lighter than traditional roofing materials like clay or cement tiles. This reduces load stress on the structure and cuts down on transportation and handling costs.

- Easy Installation (Score: 7/10) While slightly more rigid than PVC, ASA still offers easy cutting, drilling, and fastening. It’s widely used in prefabricated housing and quick-build projects where installation speed matters.

- Versatile Use (Score: 7/10) ASA’s excellent performance allows it to be used in diverse settings—from private homes and schools to resorts and public shelters—especially when color consistency and appearance are also priorities.

Together, these strengths explain why ASA is becoming the preferred plastic roofing material for projects that demand durability, climate resistance, and visual appeal.

Common Application Scenarios

Plastic roofing sheets are no longer limited to temporary shelters or small-scale rural projects. Today, with advancements in polymer science and extrusion technology, materials like ASA, APVC, PVC, and FRP are widely used across a diverse range of buildings—from urban factories to coastal resorts.

Here’s how different types of plastic roofing materials fit into real-world applications:

- ASA is favored for residential homes, villas, schools, and public buildings, particularly in tropical regions where UV damage and color fading are major concerns. Its attractive tile-like appearance also makes it suitable for visible, aesthetic-focused projects.

- APVC is commonly used in industrial warehouses, chemical plants, agricultural processing zones, and coastal facilities. Its superior corrosion resistance ensures long-term stability in harsh or polluted environments.

- PVC sheets find their niche in temporary housing, low-cost rural shelters, and emergency response buildings. Their affordability and easy handling make them ideal for projects with tight schedules and budgets.

- FRP transparent panels are mainly applied in greenhouses, livestock sheds, daylight roofs, and ventilation corridors, where light transmission and chemical resistance are essential.

- UV-PVC flat panels are designed for indoor ceilings and wall cladding in offices, kitchens, schools, and commercial interiors. They are hygienic, moisture-resistant, and visually clean.

These applications demonstrate how plastic roofing materials have evolved into a versatile roofing ecosystem—one that can adapt to both budget-sensitive and performance-critical construction demands.

Who Should Consider Plastic Roofing?

Plastic roofing sheets are not a one-size-fits-all solution—but they do serve a wide range of professional buyers, especially in developing markets where climate challenges, budget limits, and construction logistics all play a role.

Here’s a breakdown of who benefits most from adopting plastic roofing materials like ASA, APVC, PVC, and FRP:

- Building Material Wholesalers: For distributors in Southeast Asia and Africa, plastic roofing offers a competitive edge—high turnover potential, manageable inventory size, and broad applicability across multiple sectors.

- Construction Contractors and Developers: In residential, rural, and light industrial projects, plastic roofing helps contractors reduce build time, simplify installation, and offer long-lasting performance without heavy equipment.

- Importers and Project Buyers: Plastic roofing is ideal for importers supplying materials for government tenders, housing programs, and humanitarian projects, where logistics, fast delivery, and cost-per-unit matter.

- Retail Chain Suppliers and Hardware Store Networks: Because of their lightweight nature and lower breakage rate, these sheets are easier to stock, store, and sell—perfect for retailers operating in diverse geographic markets.

- Agro-industrial and Agricultural Buyers: FRP and APVC roofing is especially suited for barns, poultry houses, and greenhouse roofing, offering strength, light transmission, and chemical resistance all in one.

If you’re part of a business that values scalability, weather resistance, and construction speed—plastic roofing is likely a strategic material to keep in stock.

Buying Tips and Considerations

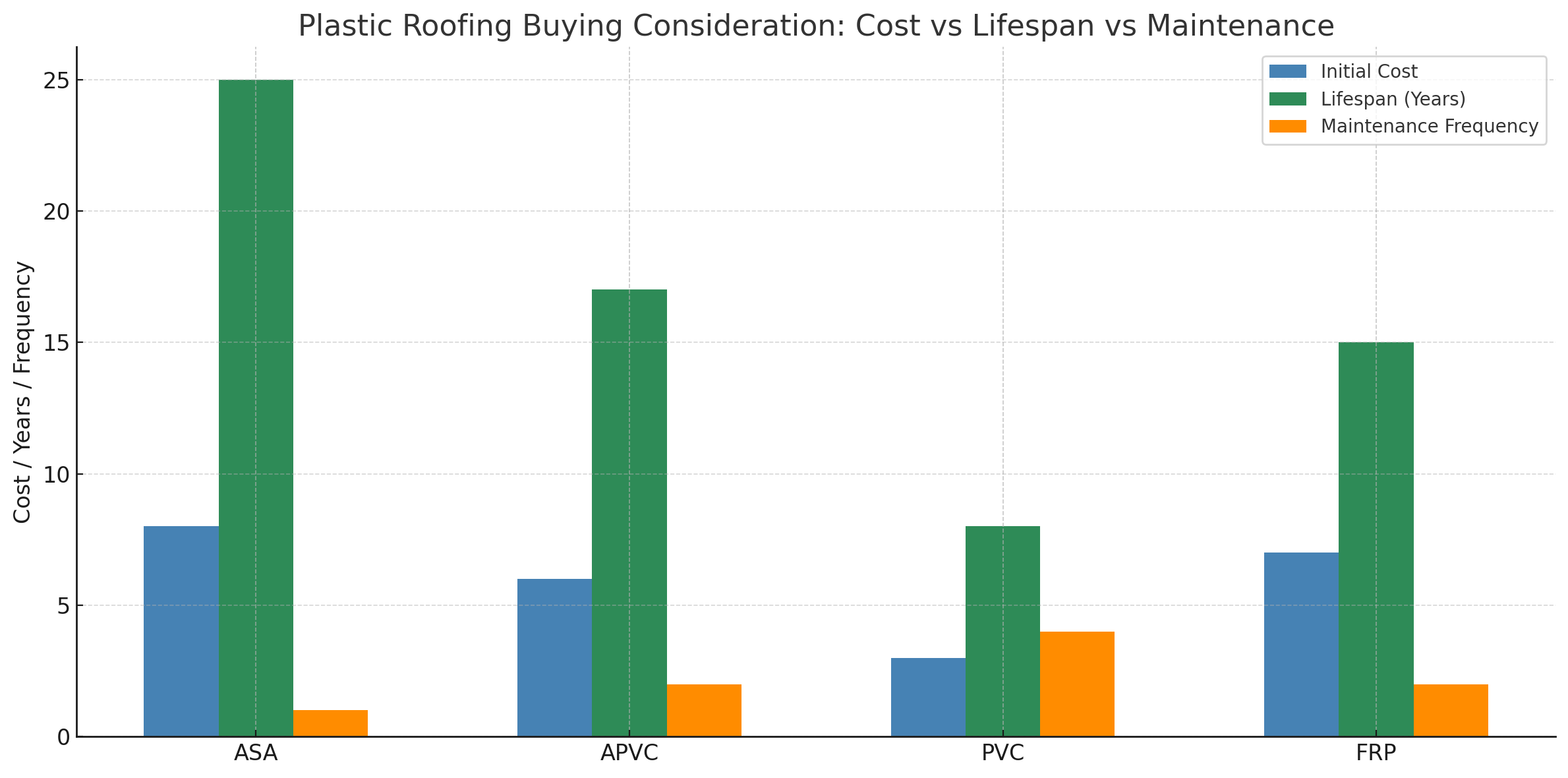

If you’re considering plastic roofing for your next project, here are key factors to keep in mind to ensure you make the right decision—for both performance and long-term value:

- Match Material to Project Needs Not all plastic roofing sheets are created equal. Choose ASA for UV-intensive areas, APVC for corrosive environments, PVC for low-cost coverage, and FRP for light transmission. Avoid overspending on features your project doesn’t require.

- Consider Installation Conditions Ensure the roofing profiles match your frame structure (metal, wood, concrete). Also, factor in on-site labor experience—PVC may be easier for first-time crews, while ASA might require more precise handling.

- Verify Quality Certifications Check for international standards such as ISO 9001, SGS Test Reports, UVAging Test Results, and other indicators of material stability. Certified materials perform more consistently and help reduce post-installation issues.

- Assess Supplier Capabilities Work with experienced manufacturers who offer clear specifications, thickness tolerances, color consistency, and packaging standards. This is especially important for bulk buyers or export-oriented procurement.

- Request Samples and Mockups Before placing large orders, always test product samples under your climate or roof angle. Some suppliers (like Duolong) also provide mockup installations or video demonstrations.

- Balance Price with Lifecycle Cost Don’t choose based solely on price per sheet. A cheaper PVC roof may need replacement in 5 years, while a more durable ASA roof could last 25 years with no repainting or sealing—total cost matters more than unit price.

Turn Insights into Action – Partner with a Trusted Manufacturer

From ASA’s unbeatable UV resistance to the cost-efficiency of PVC and the industrial strength of APVC, modern plastic roofing materials offer builders a tailored solution for almost every climate and budget. As we’ve seen, each type comes with trade-offs—so the key lies in understanding your specific project needs and matching them with the right material.

In a world facing climate extremes, material costs, and labor shortages, plastic roofing is no longer a second-choice option—it’s a strategic solution adopted by contractors, developers, and importers across Southeast Asia, Africa, and beyond.

At Duolong, we manufacture a full range of roofing panels—from ASA tiles to transparent FRP sheets—with customizable profiles, colors, and thicknesses. We support bulk orders, OEM requirements, and full export documentation.

If you’re looking for a reliable, tested, and supplier-backed plastic roofing option—contact us today to request samples or technical brochures.