aditional materials and turn to a lighter, more energy-saving and more adaptable alternative to climate change. This is exactly the opportunity for the rise of resin roof tiles.

As a new type of roofing material made of ASA engineering resin through a polymer co-extrusion process, resin tiles have excellent UV resistance, corrosion resistance, and thermal insulation properties. With its stable structure, light texture and rich colors, it can effectively cope with the strong sunlight and dusty climate in the Middle East, and remain unchanged, faded and leak-free during long-term use.

According to Duolong’s project feedback in the Middle East market over the years, many customers have said: “After using resin tiles, the air conditioning load has been significantly reduced, and the frequency of roof maintenance has also been significantly reduced.”

From the factory roofs in Dubai Industrial Park, to the commercial roof renovations in Riyadh, to the municipal public buildings in Abu Dhabi, resin tiles are replacing the status of traditional metal tiles and asphalt tiles piece by piece. This is not only an upgrade of roofing material technology, but also a reflection of the trend of energy saving and environmental protection of the entire Middle East roofing system.

This article will deeply compare the performance of metal tiles, asphalt tiles and resin tiles in the Middle East climate, and combine real project experience and data to analyze why resin tiles are becoming a rational choice for builders and buyers. If you are hesitating about the material selection for your project, this will be a professional reference worth collecting and forwarding.

Metal roofing sheets are heat-resistant, but at what cost?

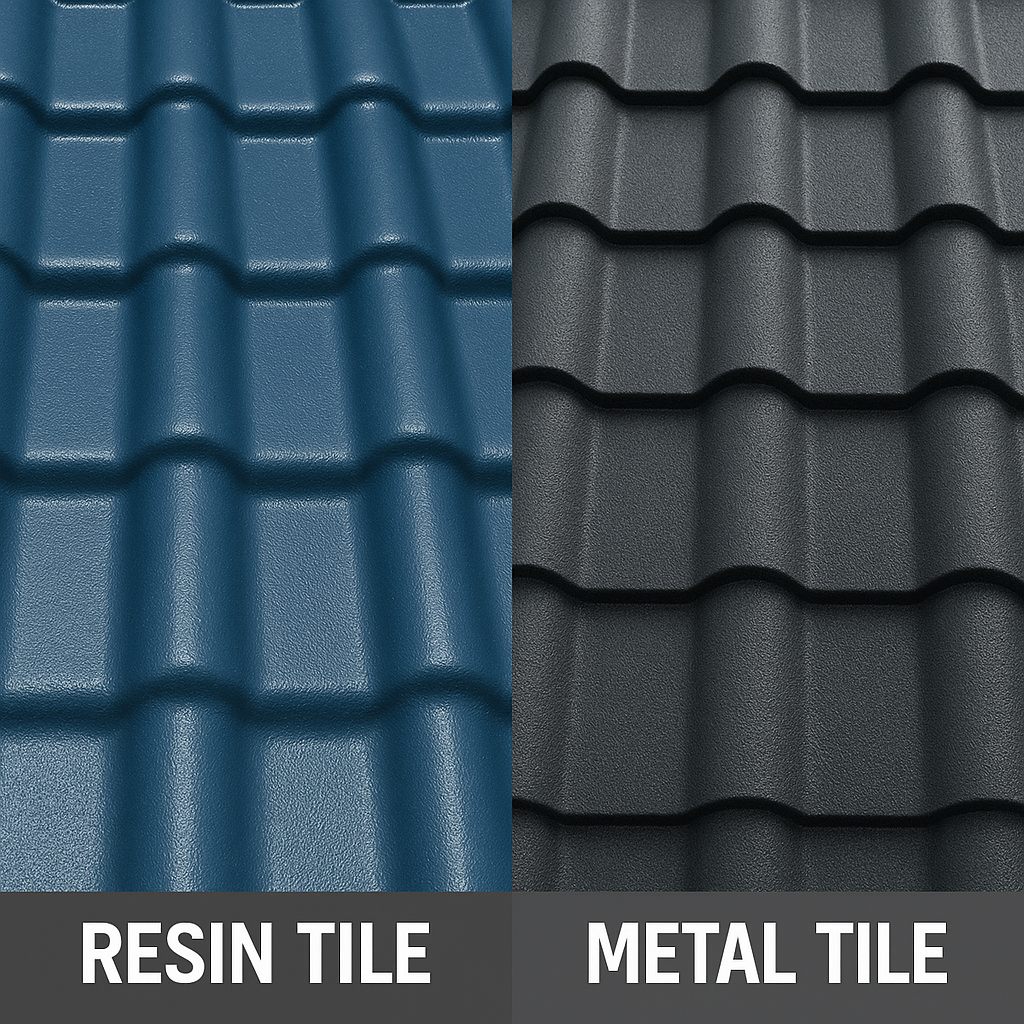

In the Middle East, metal roofing sheets have long been considered a solid solution for industrial and commercial roofs. They are indeed good at bearing weight and protecting against wind, and are still used in large-span factory roofs. However, when faced with high temperatures exceeding 45°C, strong ultraviolet radiation, and frequent sandstorms, the original advantages of metal tiles are gradually overshadowed by their disadvantages.

First, metal tiles are highly conductive to heat. In the summer in Saudi Arabia and the United Arab Emirates, the surface temperature of the roof can easily exceed 70°C. Metal materials quickly transfer heat to the room, which directly causes the temperature inside the building to rise, the load on the cooling system to increase, and the electricity bill for air conditioning to soar. This has caused significant energy efficiency losses in the operation of commercial buildings and government facilities.

Second, metal tiles are very susceptible to corrosion and aging in the Middle East environment. Dust particles and high salt humidity in the air will accelerate oxidation reactions, and even galvanized or aluminum-zinc materials are difficult to completely avoid rust, peeling, discoloration and other problems. This makes the maintenance costs accumulate year by year, especially for buildings with a project operation period of more than 10 years. It is an expense that cannot be ignored.

What is more troublesome is its noise and construction difficulty. When heavy rains suddenly hit the Middle East, metal roofs produce huge noise, which seriously affects the indoor user experience, especially in public facilities such as schools, hospitals, and mosques. In terms of installation, metal tiles require the use of special keel systems and high-strength fixings. The construction process is complicated and requires high technical skills of workers, which leads to a longer overall construction period and indirectly slows down the progress of the project.

Although metal tiles are strong, their shortcomings in thermal insulation, noise control, durability and energy saving are becoming increasingly apparent. More and more building materials wholesalers, engineering contractors and cross-border buyers in the Middle East are realizing that continuing to use traditional metal tiles means assuming higher long-term energy consumption costs and operation and maintenance burdens.

For this reason, the discussion of “resin roof tile vs metal roof” is becoming more and more frequent in the Middle East building materials market. With its lightweight, heat-insulating, anti-corrosive and easy-to-install characteristics, resin tiles are gradually becoming a new choice for builders and government project purchasers.

Asphalt shingles are cheap, but do they hide high costs later?

In projects with limited construction budgets or short-term tight schedules, asphalt shingles (asphalt shingle roofing) are often considered by buyers because of their cheap surface price and relatively simple construction. However, when the project enters the mid-to-late stage of use, more and more Middle Eastern buyers and contractors gradually realize that choosing asphalt shingles may mean taking on higher operating risks and maintenance costs.

First, the weather resistance of asphalt shingles is extremely limited. In countries with dry and hot climates such as Saudi Arabia and the United Arab Emirates, strong ultraviolet rays and high temperatures will quickly decompose the adhesive in the asphalt layer, causing fading, cracking, warping, and particle shedding on the surface. This not only affects the appearance, but also causes a decrease in waterproof performance and increases the risk of leakage.

Secondly, the service life of asphalt shingles is much lower than that of synthetic resin shingles or metal shingles. Most asphalt shingles can only maintain functionality for about 5-8 years in the Middle East environment, or even shorter. The service life of resin shingles under similar conditions can usually reach 20-25 years. This means that the apparent savings in procurement budget are likely to be quickly swallowed up in maintenance, replacement or complaint handling.

In addition, the strong smell and poor environmental performance of asphalt shingles also increase the risk of being banned in public projects. Its production materials contain a large amount of petroleum derivatives, which are easy to emit odors under high temperature conditions, which is particularly unfavorable for public facilities projects in crowded places such as schools, mosques, hospitals, etc. In some countries or regions, government purchasers have begun to restrict the use of asphalt-containing materials.

More importantly, the structure of asphalt shingles is relatively fragile, with a high breakage rate during transportation, and is not suitable for cross-border bulk transportation. For building materials wholesalers and import agents in the Middle East who rely heavily on imports, this will lead to increased storage losses and frequent customer returns and complaints, further reducing profit margins.

For this reason, “resin tile vs asphalt shingle” has become an important issue in the Middle East building materials market. More and more wholesalers and engineering contractors are giving up short-term low prices and turning to resin shingle products with better comprehensive cost-effectiveness.

As a professional resin shingle manufacturer in China, Duolong has provided solutions to replace asphalt shingles for multiple Middle Eastern projects, coordinating the entire process from design to delivery to help customers reduce long-term maintenance costs and achieve more stable returns.

Why have resin tiles become the “new favorite” of building roofs in the Middle East?

When metal tiles are questioned for “strong heat conductivity and fast corrosion” and asphalt tiles are eliminated for “short life and environmentally unfriendly”, construction buyers are in urgent need of a roofing material that combines performance and economy, and this demand is being precisely met by **resin roof tiles**.

Resin tiles are made of high-strength ASA engineering resin and are made through three-layer co-extrusion molding technology, with strong weather resistance and structural stability. In the 50°C high temperature, strong ultraviolet radiation and long-term dry wind and sand invasion environment common in Middle Eastern countries, its surface does not fade, crack or warp, ensuring that the roof is as new for many years and reducing the frequency of major repairs.

In terms of thermal insulation, resin tiles perform particularly well. Its unique molecular structure has good thermal resistance and can effectively block heat conduction. According to a third-party test report, under the same external temperature conditions, the indoor temperature of a roof using resin tiles can be reduced by an average of 5–8°C compared to a metal roof. This not only significantly improves the comfort of living and working, but also directly reduces the energy consumption of air conditioning, which is of economic value to both commercial facilities and residential projects.

In terms of anti-corrosion performance, resin tiles are not affected by air humidity, salt spray and dust erosion. Its surface is metal-free and does not contain easily oxidized materials, which is especially suitable for building roofs near the Gulf or industrial emission areas. In many industrial park projects in Dubai and Sharjah, the resin tiles provided by Duolong have not shown color difference or leakage after years of use, winning unanimous praise from local builders.

Installation efficiency is also one of the important reasons why resin tiles are popular. Compared with metal tiles that require professional tools and screw systems, resin tiles can be directly matched with traditional wood structures, steel structures and other support systems, with flexible cutting and fast laying. Usually a team of two can complete the installation, effectively shortening the construction period and reducing labor costs. It is especially suitable for engineering projects that need to accelerate the construction period during the high temperature season in the Middle East.

What is more noteworthy is that resin tiles have a variety of colors, wave patterns and thickness options, which can not only meet the aesthetic requirements of arched structures in Islamic architecture, but also are suitable for modern villas, residential areas, mosques, schools and other architectural styles, truly realizing the unity of function and beauty.

From the comprehensive use cycle, energy-saving benefits, installation convenience to maintenance costs, resin tiles are undoubtedly becoming the “new favorite” of building roofing materials in the Middle East market with better full life cycle performance. Especially for public and commercial projects with long project cycles, complex construction environments or increasingly high construction standards, resin tiles have gradually become the most promising preferred solution.

Traditional tiles are gradually withdrawing, why do Middle Eastern customers prefer resin tiles?

It is no coincidence that resin tiles are winning more and more supporters in the Middle East roofing materials market. Compared with metal tiles and asphalt tiles, the popularity of this synthetic material is the result of the joint promotion of procurement logic and actual user feedback, which reflects the real demand trend of the entire construction market for “practical, durable and energy-saving”.

In many large-scale industrial and infrastructure projects in the Middle East, construction contractors generally reflect that traditional metal tiles are expensive in terms of construction cycle, energy consumption management and after-sales maintenance. For example, in a certain industrial plant construction project in Riyadh, the contractor used metal tiles in the early stage, but in less than two years, they were partially warped and leaked due to thermal expansion and contraction, and had to be completely removed and reinstalled. After using resin tiles instead, the construction period was shortened by 20%, and the roof has remained stable to this day without additional maintenance.

In the field of building materials wholesale, many building materials markets in Dubai and Sharjah are actively adjusting their product structure, marginalizing asphalt tiles and some metal tile products, and focusing on promoting synthetic resin roof tiles as a hot-selling category. The reason is that resin tiles are lighter to transport, have a lower breakage rate, and have stable colors. They are suitable for local dealers to sell to construction sites and retail market customers, greatly reducing after-sales disputes and return rates.

**Government project parties are also inclined to choose new roofing systems with lower maintenance frequency and stronger environmental adaptability from the perspective of long-term operation and maintenance. **In the bidding instructions for an educational infrastructure project in Abu Dhabi in 2023, it has been clearly stated that traditional asphalt tiles will no longer be accepted as designated materials, but “highly weather-resistant and heat-insulating synthetic tiles” are required, which is the typical advantage of resin tiles.

The voices from residential owners should not be ignored either. In many villa projects in Dubai and Ajman, the most obvious problems reported by owners after moving in are: metal tiles are too noisy and stuffy indoors during rain; asphalt tiles fade quickly, and the overall appearance deteriorates after three years. Customers who use resin tiles generally say that the temperature difference in the house is small, the appearance is long-lasting and beautiful, and “there is almost no need to care about it.”

This change in roofing materials is no longer just a slogan promoted by manufacturers, but a real market behavior from construction parties to purchasers to end users in the construction chain. Duolong has clearly seen in its long-term cooperation with various customers in the Middle East that resin tiles are being actively accepted and preferred by more and more projects, building types and purchasing roles. The choice of the market is far more convincing than publicity.

Does choosing resin tiles mean choosing lower comprehensive costs and higher rates of return?

In the entire life cycle of a construction project, what really affects the cost is often not the initial quotation of the material, but the long-term use value and maintenance expenses it brings. Purchasers in the Middle East market are increasingly aware that choosing resin roof tiles is not only a performance judgment, but also a rational financial investment behavior.

First of all, in terms of the use cycle and maintenance frequency, the average service life of resin tiles can reach 20-25 years, and they can still maintain structural stability, no leakage, and no deformation in the strong ultraviolet rays, high temperature, and dusty environment in the Middle East. Compared with the 5-8 year replacement cycle of asphalt tiles, resin tiles almost do not require major repairs or overall replacement. In the long run, maintenance costs can be reduced by more than 70%, and operational losses caused by frequent interruptions of project maintenance can be avoided.

Secondly, in terms of construction cycle and labor costs, resin tiles can be installed over a large area in a short time due to their light weight, easy cutting, and quick splicing. Compared with metal tiles, which require a supporting keel system and precise positioning and installation, resin tiles are easy to construct and more efficient, which can effectively shorten the construction period by 10%-20%, making them very attractive for commercial projects and government projects that seek fast delivery.

In addition, Duolong’s resin tile series has good transportation safety. Even if it is shipped by sea for long distances or distributed at multiple points, it can maintain a very low breakage rate, avoiding wholesalers or distributors from encountering returns and claims during the delivery process. This has become the direct reason why many customers choose us in the Middle East market.

From the perspective of cost accounting per square meter, although the initial purchase price of resin tiles is slightly higher than that of ordinary asphalt tiles, it saves costs in four dimensions: transportation, installation, service life, and post-maintenance. One of our customers has made a detailed cost comparison in a residential project in the UAE: the comprehensive cost of resin tile roofs in 10 years is 15% lower than that of metal tiles and nearly 30% lower than that of asphalt tiles, and it is also leading in both appearance quality and functional performance.

In other words, the use of resin tiles not only saves construction and maintenance, but is also a practical means to increase project profit margins. Today, with budget transparency and long-term return orientation becoming increasingly strong, this choice is increasingly in line with the profit model of engineering contractors and building materials wholesalers. Therefore, whether you are a project manager developing a new commercial complex or a purchasing manager who controls the annual supply plan for a large building materials group, resin tiles are a material investment decision that can be quantified. Resin roofing sheet cost vs performance is becoming a pragmatic and important reference indicator in the Middle East market.

Middle East roof upgrade time, the next choice is up to you

In the extreme environment of high temperature and wind and sand in the Middle East, the choice of roofing materials is not only the basis of building beauty and structural safety, but also a long-term decision on energy efficiency, maintenance and return.

Through the comparative analysis in this article, we can clearly see that whether from the perspective of thermal insulation performance, anti-corrosion ability, construction efficiency and comprehensive cost, resin roof tiles are becoming the new standard for roofing materials in the Middle East.

In the experience of landing multiple projects in Saudi Arabia, the United Arab Emirates, Qatar and other countries, Duolong has always been a professional manufacturer to assist customers in finding roofing solutions that are more suitable for project scenarios and more cost-effective. We not only provide high-quality products, but also provide drawing adaptation suggestions, third-party testing and certification, and fast sample delivery services to ensure that every purchase is accurate and controllable without worries.

If you are looking for a stable and reliable roofing material partner for your next project, please contact us immediately to obtain samples and quotation solutions.

Let Duolong help your project roof and win at the starting point from material selection.