When Your Basement Walls Start Leaking.That musty smell when you open the basement door Water droplets forming on concrete walls Dark mold spots creeping up the corners These are more than just annoyances they signal serious problems that could compromise your homes structure and your familys health

Many homeowners dont realize that basement moisture doesnt just come from major floods Everyday humidity ground moisture and minor seepage can cause insulation to fail completely The right insulation choice can mean the difference between a dry usable space and ongoing moisture battles

Understanding Two Main Insulation Types

How XPS Creates Effective Thermal Barriers

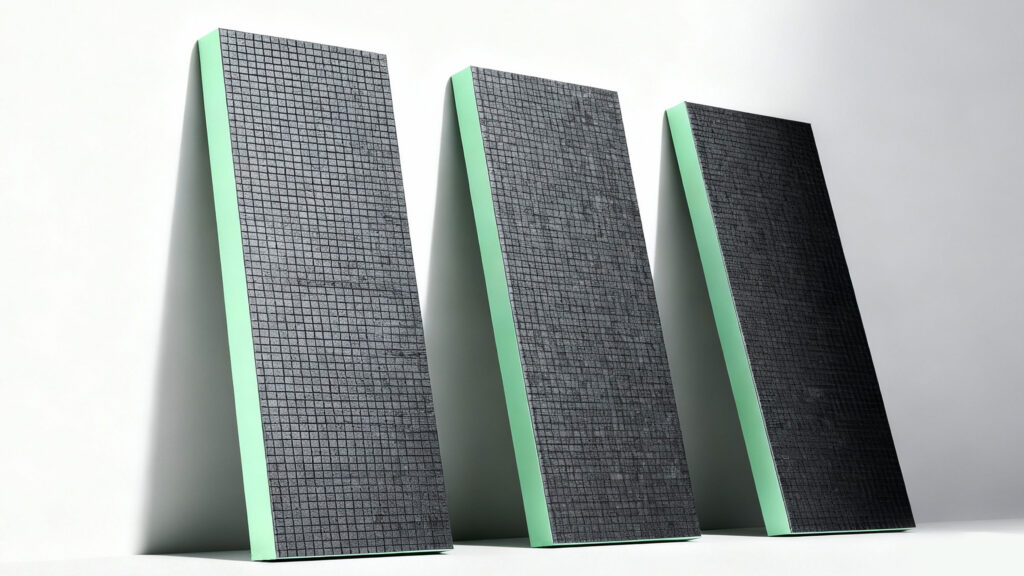

XPS extruded polystyrene boards work like a sealed thermos for your basement Their manufacturing process involves melting polystyrene resin and pushing it through a die then cooling it quickly This creates thousands of tiny closed air pockets that block heat transfer and resist water absorption

Fiberglass in Wet Environments

Traditional fiberglass insulation acts like a sponge in damp conditions The fluffy pink material contains millions of glass fibers with air spaces between them When moisture enters these spaces the insulation loses its thermal resistance and becomes a breeding ground for mold

Quick Selection Guide

| Situation | Recommended Material | Why |

| Occasional dampness | XPS | Handles moisture well |

| Constant high humidity | XPS | Maintains performance |

| Flood-prone areas | XPS | Can dry out and recover |

| Completely dry basements | Either | Both work in dry conditions |

Moisture Resistance Testing Results

XPS Closed Cell Science

Independent laboratory testing shows XPS absorbs less than 0.3% water by volume even when partially submerged for 24 hours The closed cell structure creates natural water resistance without additional treatments

Fiberglass Performance When Wet

Studies from Building Science Corporation reveal that wet fiberglass insulation can lose up to 40% of its R-value The material absorbs water like a bath towel taking days to dry completely in basement conditions

20Laboratory Test Data

| Test Metric | XPS Performance | Fiberglass Performance |

| 24-hour water absorption | <0.3% by volume | 5-15% by weight |

| Wet R-value retention | 95% | 60-70% |

| Drying time | 2-4 hours | 2-4 days |

| Mold resistance | High | Low |

Long Term Thermal Performance

Initial Performance in Dry Conditions

Both materials start with good insulation values XPS provides R-5 per inch while fiberglass offers R-3.2 to R-3.8 per inch However basement conditions rarely stay completely dry

Performance in Damp Conditions

After three years in typical basement environments XPS maintains over 90% of its original R-value Fiberglass typically shows 30-40% reduction due to moisture accumulation and compression

Five Year Performance Tracking

| Time Period | XPS R-value Retention | Fiberglass R-value Retention |

| Installation | 100% | 100% |

| 1 year | 98% | 85% |

| 3 years | 95% | 70% |

| 5 years | 92% | 60% |

Health and Safety Evaluation

Indoor Air Quality Impact

XPS boards emit no fibers or particles into the air making them safe for basement living spaces Fiberglass can release tiny glass particles during installation and if disturbed later potentially affecting respiratory health

XPS boards emit no fibers or particles into the air making them safe for basement living spaces Fiberglass can release tiny glass particles during installation and if disturbed later potentially affecting respiratory health

Mold Resistance Testing

Laboratory mold growth tests show XPS supports virtually no mold growth even at 95% relative humidity Fiberglass backing paper and the insulation itself can develop mold within 48 hours when wet

Installation Safety

XPS installation requires basic safety gear gloves and eye protection Fiberglass installation demands full protective suits respirators and careful containment to prevent fiber dispersal

Practical Installation Guide

XPS Standard Installation

Measure and cut panels using a utility knife

Apply construction adhesive to wall surfaces

Press panels firmly into place

Seal joints with approved tape or sealant

Install finishing wall covering if desired

Fiberglass Installation Steps

Measure and cut batts keeping them slightly oversized

Press batts between studs ensuring complete filling

Install vapor barrier over insulation

Seal all edges and seams carefully

Add drywall or other finish material

DIY Feasibility Analysis

XPS installation ranks as moderately easy for DIYers The rigid panels are simple to handle and cut Fiberglass installation proves more challenging requiring precise fitting and comprehensive safety gear

50Common Installation Mistakes

| Error | XPS Consequences | Fiberglass Consequences |

| Gaps between insulation | Reduced effectiveness | Thermal bridges |

| Poor vapor barrier | Minor impact | Major moisture issues |

| Compression | Minimal effect | Significant R-value loss |

| Incomplete sealing | Some efficiency loss | Mold risk |

Long Term Cost Analysis

Initial Investment Comparison

XPS costs approximately $0.50-$0.70 per square foot installed

Fiberglass runs about $0.30-$0.50 per square foot installed

While fiberglass seems cheaper initially long term performance tells a different story

Maintenance and Replacement Costs

XPS typically lasts 20+ years without replacement

Fiberglass often requires replacement within 5-10 years in damp conditions

Replacement costs can double the total investment over 20 years

Total Cost of Ownership

| Cost Category | XPS 20-Year Cost | Fiberglass 20-Year Cost |

| Initial installation | $1,500 | $1,000 |

| Replacement | $0 | $1,000 |

| Energy loss | $500 | $1,200 |

| Mold remediation | $200 | $800 |

| Total | $2,200 | $4,000 |

Special Situation Solutions

Severe Moisture Problems

For chronically wet basements combine XPS insulation with proper drainage systems and dehumidification The insulation works as part of a complete moisture management strategy

Older Home Renovations

Historic homes require special consideration XPS provides good moisture protection while allowing walls to breathe properly unlike some vapor barriers that trap moisture in old masonry

Working With Waterproofing Systems

XPS complements interior waterproofing systems without interfering with their function The rigid panels protect waterproofing membranes while adding thermal benefits

Making Your Final Choice

Assessing Your Basements Condition

Start by determining your moisture level

Place a plastic sheet against the wall for 24 hours

Check for condensation underneath

Measure humidity levels over several days

Look for existing water damage signs

Simple Material Selection Guide

High moisture = Choose XPS

Occasional dampness = XPS recommended

Completely dry = Either material works

Budget primary concern = Consider long term costs

Key Purchase Parameters

For XPS look for

Compressive strength 25 psi minimum

R-value consistent throughout panel

Moisture absorption under 0.3%

Proper certification marks

XPS Advantages in Damp Environments

Proven Moisture Performance

XPS maintains thermal performance in wet conditions that would ruin other insulation types Its closed cell structure provides permanent protection against moisture damage

Wide Application Range

From basement walls to below grade installations XPS handles various moisture challenges while providing consistent insulation value

Long Term Value Protection

10By choosing XPS homeowners protect their investment against moisture related damage and ensure energy efficiency for decades

Selecting Quality XPS Products

Five Key Quality Indicators

Compressive strength minimum 25 psi

Consistent thickness throughout panel

Square edges and uniform dimensions

Third party certification marks

Manufacturer warranty coverage

Moisture Performance Parameters

Look for water absorption testing results

Verify long term thermal resistance data

Check for mold resistance certification

Confirm fire safety ratings

Recommended XPS Brands

Leading Manufacturers

- DuoLong

- Owens Corning

- Dow Chemical

- Kingspan

- Hunter Douglas

Additional Quality Options

- CertainTeed

- Pactiv

- Nexkemia

- Jackon

- Unilin

Why XPS Typically Performs Better

Comprehensive Basement Advantages

XPS addresses multiple basement challenges simultaneously providing thermal insulation moisture protection and durability in one product

Scientific Support and Validation

Independent testing and decades of field experience confirm XPS superior performance in below grade and damp applications

Long Term Investment Value

While costing slightly more initially XPS proves more economical over time through maintained performance and reduced maintenance needs

For basement insulation projects where moisture may be present XPS provides reliable performance that protects your home and your investment making it the smart choice for most homeowners